Incremental learning

I guess life would be boring if it weren’t so complex. I don’t mean that everything is difficult, but that the things we enjoy have variety through complexity. Capability too. The things we take for granted are the result of years of development, the latest model was designed by somebody who “stood on the shoulders of giants”.

I’m involved in a lot of things, maybe too many. My trade is perhaps the most diverse in the world. I’m an old school sign painter, which if I let it, would incorporate these things in their advanced stages: woodworking, metal working, art, typography, advertising, computers, plotters, pinstriping, sculpting, theme park work, silkscreening, neon, electrical signs and controls, cartoons, automotive painting, and other stuff I’m sure. Each of these things requires a bit of ongoing leaning, and gets fun when you tie them together. For instance, I like to hand draw artwork for my own clip art. I make it into a vector file that can be enlarged to any size, and used in a plotter to cut vinyl graphics, or on an engraving machine or embroidery machine.

One of the subsets of painting is restoration; and the tools used therein. In the last couple years, I’ve discovered the practicality of wire brush wheels on a 4 inch angle grinder. The wire wheel comes in two basic variations, which makes for four types. There’s flat shape or cup shape, there’s braided wires, or straight wires. From my experience, the braided flat wheel is the most aggressive, and the unbraided cup shape is the least aggressive. Only recently have I started to think that there’s value in the softer model. Before, it was just a slower way of cleaning things. And clean it does. If I can put a video in a hosting directory, or open a utube account, I’ll edit this post with a link to a video I made of big steel push rods on a steam locomotive being cleaned with a wire wheel.

So I was doing a couple restoration projects on Saturday; my 1951 Chevrolet truck, and a metal lawn cart with the kids. SEE HERE. First, I was doing the body work of the Truck. I remembered that the unbraided wire wheel works for removing vinyl stickers from a car finish; so I wondered if it work to clean the old truck tires. These tires had this permanent tan colored grunge look. It wouldn’t scrub off. A more aggressive wire wheel would tear up the rubber tire, but the softest cup type didn’t. It got around the raised letters without damaging them. the results were pretty good compared to the grunge look.

Then I went and worked on the cart project. The last step was to clean up the tires. I grabbed the closest cleaning product, which happened to be Zep Fast 550. It cleaned the tires very well, and I wondered if it would work for -really- old tires. Below are some pictures, but as is often the case, the lighting hides part of what you want to show. So it is, these tires looked worse than they do in the first picture. The second picture is black primer, and there’s an aluminum strip in one picture, it’s REALLY handy for keeping paint off the tire. I liked the results so much that I did all 4 wheels on my Toyota truck.

In the book of Isaiah, chapter 28, it talks about incremental learning. Here’s what it says:

9 Whom shall he teach knowledge? and whom shall he make to understand doctrine? them that are weaned from the milk, and drawn from the breasts.4 10 For precept must be upon precept, precept upon precept; line upon line, line upon line; here a little, and there a little

The Bible always has some new thing to learn; relevant things. Right now I’m learning about the word “stumblingblock”. It’s a Biblical term about people who have a warning, but disregard it. Good stuff, very relevant to these times.

What you’re seeing are two benches. The closer one is wood, and has a motor and grinder mounted on it. The second one is steel, it has a jointer on the closer end; and a table saw on the end closest to the gold van. The lower shelf has a large electric motor.

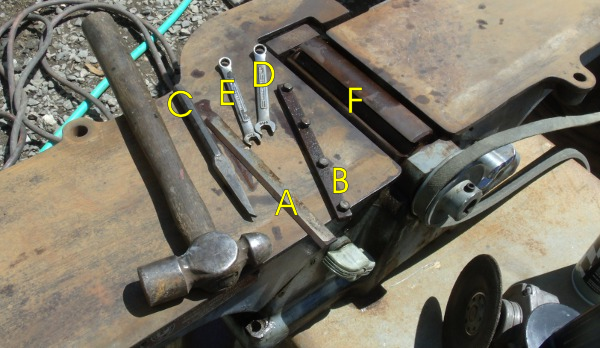

What you’re seeing are two benches. The closer one is wood, and has a motor and grinder mounted on it. The second one is steel, it has a jointer on the closer end; and a table saw on the end closest to the gold van. The lower shelf has a large electric motor. Here’s what was difficult: All these tools and parts are setting on half of the jointer top, This half raises and lowers at an angle, The places where it contacted the jointer body were rusted together. After setting a week with penetrating oil, the parts became free, and will now move as needed. I’ve never had good results using the oil this way, until today.

Here’s what was difficult: All these tools and parts are setting on half of the jointer top, This half raises and lowers at an angle, The places where it contacted the jointer body were rusted together. After setting a week with penetrating oil, the parts became free, and will now move as needed. I’ve never had good results using the oil this way, until today.