Here’s a link to a page at this site that has a free vector file of this image. That file can be used for all kinds of things, which are explained a little on the page.:

Here’s a link to a page at this site that has a free vector file of this image. That file can be used for all kinds of things, which are explained a little on the page.:

This is for cogofwar and no doubt others.

I’d love to talk about this, but first a story: A lonnnng time ago, a relative passed away. My mother wanted to go & help, so she took us kids with her. The adults were out doing stuff, there was nothing made for lunch. So I told my brother & sister that I would cook some hot dogs, which I did. As they took their fist bites, they were chewing very slowly, and expressed how poorly the results were. Me, being Mr. non articulate, blurted out: “It’s not my hot dogs, it’s my cooking!” INSTANTLY riotous laughter broke out w the 2 of them. I tried to clarify by saying that I meant It’s not my fault, all I did was heat them up.

Looking at my first comment in the thread at SG, and its attempt at self deprecating humor, I realize that the comment also fits your situation very well. I know it does because I’ve encountered a very similar situation myself. You are not alone in this thing. Your use of the word gaslighting, along w the other things you said, tells me enough. I want to strongly emphasize my desire to not get any more specific about the details of what you’re dealing with at Social Galctic. I like the folks at Social Galactic, they’re a great crowd, I don’t want to spread thoughts that would require a big clean-up there. If you want to talk details, use the comment section below or contact me at: metamorphic2010@hotmail.com

I think it’s safe to assume all the people you mentioned aren’t friends you know well. Think about that. Now think about the odds of them all consciously working in concert. It’s v low to none. What you are dealing w is very real, but it’s not from people alone. If you haven’t thought about this before, it’s some scary ‘stuff’, but again, it’s very real.

A long time ago, a guy was sold into slavery by his own brothers. He couldn’t understand, why, because he wasn’t a really bad guy. Fast forward, he is freed and prospers in the new country. Years go by, & his brothers show up needing help. When he finally reveals who he is to them, they’re terrified. But he says to them “You meant it for bad, but God meant it for good”.

You could roll your eyes or even spit on me for what I’m about to say, but it’s true. You will make it through this, & it will help you. This thing you’re dealing with is from Satan. Yeah, that Satan. Most people, millions of them, go through their existence never knowing how real and immediate the supernatural real is. You will never again be one of them.

I don’t know your spiritual situation, maybe you encountered some church people when you were a kid, I don’t know. But I want to say this uninterrupted, so I’ll just continue. Just as the darkness is real, so is the God who created all we see. Darwinism is nonsense in so many ways. It’s a self contradicting theory involving beneficial mutations. So there’s a critter with front legs that are half wing, half leg. This thing can actually eat better that his fully legged bros? These mutations happen over thousands or millions of years, that’s a lot of time to be on a starvation diet. Who’s idea was it to gradually make a wing anyway? Did critter bro go hopping around a lot, so “Hey I need wings”? And who even even knew what a wing was? Hmmm, the plot thickens…but gets worse. Critter bro is starting to age a bit, can’t hop like he used to. AMAZINGLY, he finds the one and only she critter with the exact same mutation. Wowser. Love at first sight, yada-yada, along comes baby half wings, The story doesn’t have to continue to absudity, because it already is absurd.

Now consider the human eye. The microbiologist Michael Behe says this:

When light first strikes the retina a photon interacts with a

molecule called 11-cis-retinal, which rearranges within picoseconds

to trans-retinal. (A picosecond is about the time it takes light to

travel the breadth of a single human hair.) The change in the shape

of the retinal molecule forces a change in the shape of the protein,

rhodopsin, to which the retinal is tightly bound. The protein’s

metamorphosis alters its behavior. Now called metarhodopsin ll,

the protein sticks to another protein, called transducin. Before

bumping into metarhodopsin ll, transducin had tightly bound a

small molecule called GD}? But when transducin interacts with

metarhodopsin II, the GDP falls off, and a molecule called GTP

binds to transducin. (GTP is closely related to, but critically differ~

ent from, GDP)

GTP-transducin-metarhodopsin II now binds to a protein called

phosphodiesterase, located in the inner membrane of the cell.

When attached to metarhodopsin II and its entourage, the phos-

phodiesterase acquires the chemical ability to “cut” a molecule

called cGMP (a chemical relative of both GDP and GTP). Initially

there are a lot of cGMP molecules in the cell, but the phosphodi-

esterase lowers its concentration, just as a pulled plug lowers the

water level in a bathtub.

Another membrane protein that binds cGMP is called an ion

channel. It acts as a gateway that regulates the number of sodium

ions in the cell. Normally the ion channel allows sodium ions to

flow into the cell, while a separate protein actively pumps them out

again. The dual action of the ion channel and pump keeps the level

of sodium ions in the cell within a narrow range. When the amount

of cGMP is reduced because of cleavage by the phosphodiesterase,

the ion channel closes, causing the cellular concentration of posi-

tively charged sodium ions to be reduced. This causes an imbalance

of charge across the cell membrane that, finally, causes a current to

be transmitted down the optic nerve to the brain. The result, when

interpreted by the brain, is vision.

if the reactions mentioned above were the only ones that operated

in the cell, the supply of 11-cis-retinal, cGMR and sodium ions

would quickly be depleted. Something has to tum off the proteins

that were tumed on and restore the cell to its original state. Several

mechanisms do this. First, in the dark the ion channel (in addition

to sodium ions) also lets calcium ions into the cell. The calcium is

pumped back out by a dillerent protein so that a constant calcium

concentration is maintained. When cGMP levels fall, shutting dowr

the ion channel, calcium ion concentration decreases, too. The phos

phodiesterase enzyme, which destroys cGMR slows down at lowe

calcium concentration. Second, a protein called guanylate cyclase

begins to resynthesize cGMP when calcium levels start to fall. Third,

while all of this is going on, metarhodopsin ll is chemically modified

by an enzyme called rhodopsin kinase. The modified rhodopsin then

binds to a protein known as arrestin, which prevents the rhodopsin

from activating more transducin. So the cell contains mechanisms to

limit the amplified signal started by a single photon.

Trans-retinal eventually falls off of rhodopsin and must be recon-

verted to 11-cis-retinal and again bound by rhodopsin to get back to

the starting point for another visual cycle. To accomplish this, trans-

retinal is first chemically modified by an enzyme to trans-retinol—a

form containing two more hydrogen atoms. A second enzyme then

converts the molecule to 11-cis-retinol. Finally, a third enzyme re-

moves the previously added hydrogen atoms to form 11-cis-retinal,

a cycle is complete. U

That’s just the chemical process, the parts of the eye are extremely complex too. They all have to be together to work, if one part is missing, none work. How did these parts know they needed to evolve into a complex thing?

There is a God who made all these things, and He didn’t just walk away afterwards. I’ve been a Christian for more than thirty years, I still have difficulty understanding how much He wants to interact with me. My thoughts always were like He’s so important that I’d better only take life and death type problems to Him. He’s the opposite of that, it’s amazing, really. But it has to be on His terms. We can’t put together our own Smosgasbord of religious snippets and bits of philosophy to interact with Him. His terms as thus: We’re all separated from Him by selfish choices we’ve made. A lot of times the word sin can be spelled self, because we’re disregarding God and others. Once we’ve crossed the line, that’s our label, we have to wear it. There’s no pretending we never acted that way.

Since we can’t go back over that line, the consequences are eternal. From what I understand, there are different degrees of hell, but it’s all miserable, because it’s permanent. God cared very much about this situation, so He came to earth as a man, lived a perfect life, then was falsly accused and crucified. What was going on in the unseen realm is that Jesus was voluntarily trading His perfect record for our sinful record, if we’re willing to accept it. It means repenting of sin, and getting a new life, a real one.

If you haven’t already, it would bring me joy if you talked to God about this .

Not only will you be part of His kingdom, but His spirit will help you understand things around you. I can help some, but you’re in a serious situation. I’m just a guy behind a keyboard who is also paying bills and doing chores. He is the help that is there any day, any night, always.

Satan is “The father of lies” and trust me, he’s good at it. When you or I think about lies, we think of deceitful, false words spoken by people to trick you into choosing B when you should have chosen A. Satan and his workers can be more sophisticated than that though. A crude example would be that they hide option A, create option C which looks and is really bad, so that you’ll choose option B, which is empty or less destructive than option C.

Now back to this gaslighting. They typically have a few operatives on the ground, who say things which are intended to make you feel bad in one way or another. Again, I’ve seen the details, mine situation might have been a little different than yours, but it was really bad. I have reasons for not publicly discussing the details, so please work within those parameters.

After their real operatives say what they do, then the crew of unseen operatives starts to work. These beings don’t die at age 80 or whatever, they’ve been around awhile, and they have experience. (I think) they work in groups on an assignment, unfortunately, it sounds like you were one of their assignments. They very carefully arrange circumstances in peoples’ lives so that the stuff they’re talking about is exactly like some everyday details of your life, and it sounds like they’re consciously working against you. Some are just shallow rude people, and the stuff they talk about applies to a lot of the people around them. There are some awful people out there, but most are just part of something they’re not even aware of.

You will recover from this operation, but not in ten minutes or an hour. The Bible says that if we resist the devil, he will flee. Right now, that’s the key to resisting. I want you to have this thought, it doesn’t have to be a big phony Tony the Tiger roar, just a calm unmovable inner resolve that says “You scum buckets didn’t get me yesterday, or the day before. You won’t get me today or tomorrow either.” Doing with a little steely anger helps. Think it, keep it. Keep it later today, and keep it tomorrow.

Along with this resolve, be in prayer asking God to give you wisdom and understanding about all this. He will. It unravels pretty quickly but think about it. Even if the operatives dropped everything instantly, you’ve been dealing with some heavy hairy stuff by yourself. That’s going to take a little while to readjust from.

Now you’re more aware of the supernatural than most will ever be. God can use that. It will help you take His word very seriously, and help you realize the importance of doing God’s work in this world. This has been really long-winded, but it’s the most effective way I can think of to say it. I did all this, and you can too, feel free to talk about it here in the comments or at my email.

Not great pictures, but I made a lot of progress over the weekend. I might have invented a new way to make outlines: Use a blunted hypodermic needle with paint in it.

Next will be some fun lettering on the sides. Took me 7 tries to get 1 design the way I wanted it.

I’ve been working on these big tusks/front bumper since last year, at least I haven’t counted how many hours, probably more than 100. Maybe 120 or 140. Tonight I finally started applying white paint. Like other projects, every time I thought I was finished with a certain step, I realized it needed some touch-up or an additional process.

Here are some pictures. the first is of two teeth laying on a bench sander. I didn’t think this tool would be helpful, but it was very helpful if handled very carefully. I used it to shape the body putty on the side of each tooth. there’s a slight bulge there, to hide the corner where the steel pipe bends. At the back of the table, you can see the brand of putty (Bondo) I used. This brand is new to me; from the UK I think. I’ve been very pleased with how it handles, and will certainly buy it again.

Next is a picture of the just welded, but not painted teeth on the truck, At that point I realized I had to add two upright stanchions to attach a grill and body panels to.

Finally, I was able to start painting. I’m using Rust oleum semi-gloss white with other colors added, along with a hardener from Tractor Supply. It’s very close to being finished. It might need two angled brackets below it, and a grill made of expanded metal, and a couple of curved blue panels below the headlights.

Here are some projects, pictures, and thoughts from the first week of April:

Every time I think we’re done spitting firewood for the year, it gets cool again. Each year we end up with an area that’s covered with bark and kindling where we split.

Every time I think we’re done spitting firewood for the year, it gets cool again. Each year we end up with an area that’s covered with bark and kindling where we split.

I was asked to make a logo of a welder in a basket welding an I bean that’s held up by a crane. I knew I would want to see it from different angles before I chose the best one. I have some ability to draw things like this without photos to look at; but I might get some angles wrong on this job.

So I made a model scene form cardboard and wood, along with the kid’s toy pirate guy. I WAS WORKING, this is NOT PLAY, regardless how much it looks that way.

It was a good arrangement, since I normally draw in two point perspective, but I got some nice three point angles. Here’s the progress so far, the customer immediately liked it.

Someone on social media mentioned how much synchronicity they were seeing these days. That’s where you see interesting coincidences in everyday life that you KNOW are beyond mathematical probability. Some thoughts about this: I think there are at least three versions of this. The first is from God, the Creator of Heaven and Earth. The second is similar, but like Pharoh’s magicians imitating the miracles of Moses, it might not be from God. The third is man made. This evening I read a political article that was the typical doom-ish sort of thing. Then after scrolling down, found another article that was posted earlier. They both have the same key phrase. To use synchronicity in an ominous way, all a human actor would have to do is make a search for the key term, then pull up a dreary article and link to it.

Now about synchronicity that is from God, I learned a thing in the last couple of years. There was someone I knew who was very ill. I prayed for God’s healing, but it didn’t happen. There may have been obvious reasons why He didn’t heal this person, but I came to a realization: We often get what I now call “presence miracles” to remind us of His presence, but they’re not the same as miracles of intervention.

Speaking of doom, I’m not the only one who is starting to regard most of the federal or global events as a big scripted circus, or ((circus)). I thought the script was to distract, and indeed it is, but it might also be to keep people addicted. “Quick, they’re losing interest faster than before, roll out Ricky Vaugn and Trump’s indictment in the same week.” “As that wears off, put the one about a classified leak regarding Ukraine in ring three.”

There is so much that can be done to resist and overthrow this thing without being constantly focused on the three-ring circus, but I’ll relate that later. There are so many neat projects that I’m doing, it’s easy for them to dictate my schedule by things like weather or materials availability. Last night I had this thought: Do that which you would want to be found doing upon the Lord’s unexpected return.

One of those projects is to make a meat slicer to make jerky. I decided to use a piece of Spanish Cedar I was given a year or two ago. It had a rough sawn surface, so I didn’t realize how the wood looked until I sanded it earlier. I’m always amazed at tight annual growth rings this close together, if that’s what these are. This has one coat of spray lacquer.

That’s enough for now, more later. Thanks for stopping by.

That’s enough for now, more later. Thanks for stopping by.

First, just a neat picture of a ladder and its shadow:

Update: I drove the 1951 truck for the first time today. It was just a test of some brake parts, but I’ve had it for about 7 years without driving it. Here it is parked in front of the house after being parked by a fence for the last several years.

Update: I drove the 1951 truck for the first time today. It was just a test of some brake parts, but I’ve had it for about 7 years without driving it. Here it is parked in front of the house after being parked by a fence for the last several years.

Next, a picture of the large wheels and tires for that truck. These were really bad looking just before this picture was taken. I use degreaser on the tires, clean rust off the wheel with an 11 amp angle grinder and wire wheel, then spray paint the wheel silver.

I might be very close to driving it, the brakes being the last thing preventing that. The original vacuum boosted master cylinder was a two piece thing. I have the parts, but it’s just difficult to find a rebuild kit. Intereastingly, I think Isuzu used the same Bendix brake booster into the 1980s. I might be able to find a rebuild kit for those, but they’re probably in metric, and I’d have to find a way to compare measurements. It was easier to usre a big master cylinder from a 1999 Ford pickup.

Finally, there was an odd incident in early march involving Mourning Doves. There were two that couldn’t fly well at all, they could only hop a few branches away at a time. There were also two healthy doves that acted as though they were trying to help the less able ones.Being that they were all the same size, if anything, the less able ones were larger; and the time of year it is, I was doubtful that the two less able ones were offspring of the other two. The two more capable ones acted like parents do when their young are learning to fly.

My concern of course was that the toxins from the Ohio train wreck might have affected the brirds. This is east Tennessee, south of Knoxville, so it’s not a solid explanation, but I’ve never seen anything like it before. The top picture is the two less able doves, the bottom picture is one of the more capable.

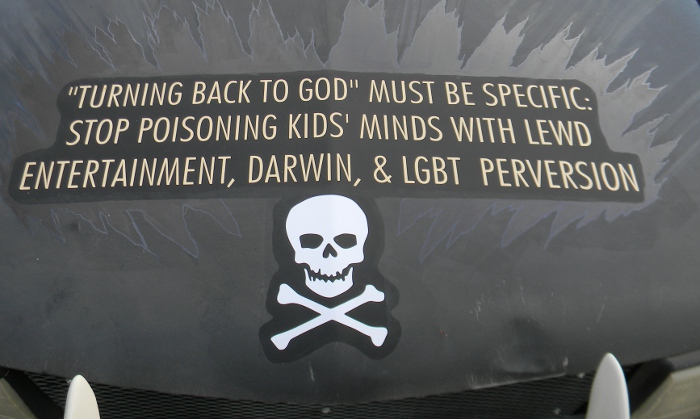

My mother in law is 90 years old. She was one of the pioneers of home schooling. It was considered strange or neglectful back then. It took courage to do something different. In a country of so much apathy,home schooling is an effective act one can do now.

She looks sad in the picture but it was tears of joy; she really did like the award. The thing is, it was so low cost to make, yet a lasting and unique way to show one’s appreciation. The big lunk is yours truly, this is one of the best things I’ve ever done.

Years ago I thought about the phrase “In gun we trust” to describe trusting solely in widespread gun ownership as protection from government tyranny. I’ve been studying politics more, and now see another aspect of the phrase.

The first intent of the phrase was to address those who want freedom from overbearing government, but who disregard God by bringing the same entertainment in their homes as the ungodly, by sending their children to the same anti God schools, who live lives indistinguishable from their secular neighbors. The same two incomes, debt, houses, cars, everything save church attendance. In another post I made a case that Christ left the USA to its own devices in the early 1960s due to changes in government schools.

The second aspect of the phrase is about inactivity. I wonder if the right isn’t playing into the hands of darkness by waiting and waiting for a coming civil war and not putting serious thought toward other actions in the interim. I have no aversion to armed resistance, and I know a little about the hardware involved.

Another page of resistance ideas

With the raid of Mar A Lago, some wondered if there is truth in the Q idea. Maybe we’ll all know in two weeks’ time. It occurred to me that it’s all a movie, that Trump, Q, and the left are all on the same side, and that he will be reinstalled. Then, those on the right will have a sigh of relief, but the fed monster that Lincoln created will still be in place. The people will have jobs, domestic oil, and 2 dollar a gallon gas. But the department of education will still be in place, mandating the abominations of Darwin and LGBT. Those abominations are the millstone tied around America’s neck, which will be the end of us. Satan will have his way, the right will be divided and Christians will be a segregated minority.

OK, I have no way of proving whether the minority part is true, and frankly, I’m a bit over all the speculation, I’m over the political soap opera known as “Distraction of our lives”. This week’s installment is the migrants sent to Martha’s Vineyard. For me this idea that “the movie” is sinister is a working assumption. If that’s a wrong assumption, the goals I have won’t conflict with those of anyone who is doing what is right. Jesus said: Be not careful therefore for the morrow, for the morrow shall be careful about itself. Sufficient to the day is its own evil. Have you ever thought about that verse in terms of doing what you can today, while not knowing exactly what will happen six months from now or a year from now?

There are many memes and comments on the internet about the second amendment. Do you suppose the founding fathers never heard of the phrase “The pen is mightier than the sword”? Notice what’s in the amendment prior to the second. Yes, I’m aware of the extent of the corruption, and that we probably won’t vote our way out of this, but there is damage that can be done to the cabal other than shooting them. How do we really know how daunting the cabal is if we haven’t seriously investigated its strengths and weaknesses? How many have done an internet search for “non violent revolution”? How many have done a comparison of the Polish shipyard strikes to the Canadian truckers’ incident? How many have a good grasp of the demographics of legacy news media viewers?

It’s obvious that the the powers that be want to destroy the U.S. It would be no surprise if they have plans in place for after that collapse. Things like a new currency, maybe completely digital. How many of us have contacted local banks or businesses about establishing a local currency under those circumstances? I haven’t yet. What if the credibility of the news media was completely destroyed? How would this affect the cabal’s operation in a hot conflict? They would be attempting to use propaganda to vilify resistance, to hide their own dark operations, to make the populace terrified or complacent. Acting now to destroy the credibility of the legacy news media will have a direct affect in a civil war. Acting today to destroy the credibility of the legacy news media is fighting in that conflict NOW.

Do you want to affect that conflict now, rather than waiting for it to arrive? Then start analyzing the strengths and weaknesses of the destroyers’ influence, how they manipulate people and retain allies. Of course, the activism that is appropriate for one is not for another. If you have young children, that’s a big consideration, if you don’t know who to trust with your thoughts, or how to safely relay them, think about that first. I’ve met intelligent people online, many are smarter than me. Imagine if the cognitive power of the right was utilized to analyze the weaknesses in the left’s institutions. I’m not sure that we’ve even gone half way there.

I have already been working against the credibility of the left, away from the internet and am working on efforts to counter the false science narrative. I was asked the other day what can be done in the face of such apparently daunting control. I realized that to say we need to analyze the strengths and weaknesses of the left is vague. We need to first recognize the the components of their operation, the determine the weaknesses of each component.

I made a primitive diagram, it’s a start. You can see it below. In it, you see the central power and the outlying components of the operation. Each component has two arrows, one is what the central power pays, the other is the expected return. The tasks and rewards are obvious to anyone who has been watching; things like wages, wealth and job security are received for enforcing the system. What’s not obvious are the details of the exchanges. Those are the targets. Below are a few ideas of how to weaken or destroy the exchanges, but more ideas are needed.

I am a Christian, God helps me with things I’m working on. I’m in the process of reading “The case for a creator” by Lee Strobel to my sons along with our bible study. In chapter 7 there is talk of the ability to discover (I will call this AD). That’s the observation that not only has the world been designed and created in a precise and amazing way; but that it was made in a way that man can learn about its secrets. I wondered what would happen if I prayed for AD in the projects I’m working on.

I got great results in two of my projects. Now I’m asking for His help in this one. So far it appears that there are strengths and weaknesses in the exchanges of the system that should have been obvious before, but I overlooked them. Where you see ADA below, those are instances which I think are an answer to prayer for AD. Some of these ideas are so sudden that they seem beyond what I’m capable of thinking.

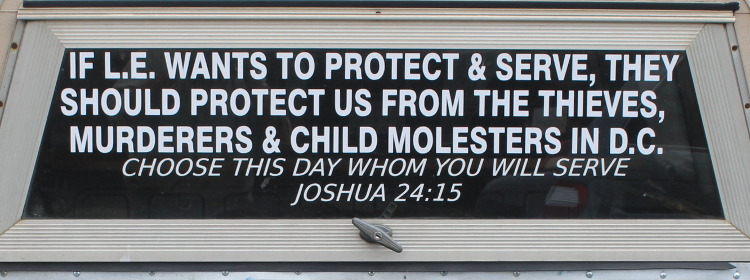

As I said, I’ve been making signs for awhile, here’s a link. I’m in an interesting location as far as reaching people with the medium of signs. Below is a picture of a recent sign. The ADA realization that came after I made it; is this: Big Pharma is a huge problem in this country, with their deadly agenda and ability to buy politicians. But where are most of their sales? Isn’t it through prescriptions written by doctors? How much is over the counter sales? If the public loses trust in doctors, this could weaken Big Pharma.

More ADA: One of the most important parts of marketing is to know where your customers are coming from; which advertisements they’re responding to. A keen employer will have his employees always politely ask people “So how did you hear about us?”

Suppose that you wanted to target the finances of a lying media outlet. So you see who their biggest advertisers are. If you were to boycott them, it would create hostility toward your cause. What if instead, you helped the advertiser to know where their customers were really coming from? There are a lot of wasted advertising dollars spent. Then, you would be a friend who is helping. If it turns out that the media outlet is working for them, you won’t have made an enemy, and they might be open to other marketing suggestions.

These are just a few ideas. Imagine if the smart people in the Dissident Right prayed for the ability to discover ways of engaging and damaging the institutions of the evil agenda? If we truly knew the workings of the enemy, and knew ourselves?

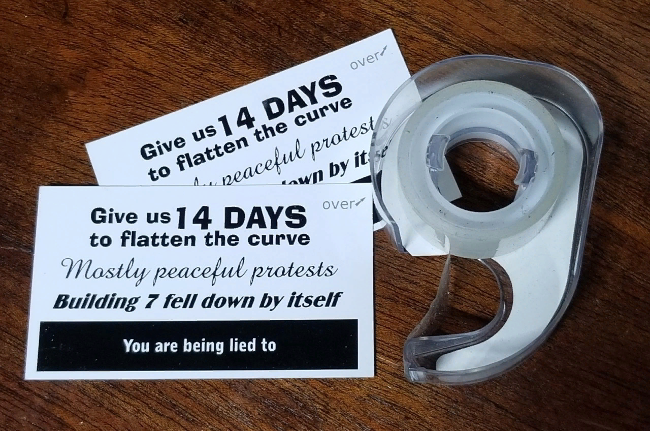

Below are pictures of signs I’ve made and cards I distribute. Cards are easier and less expensive than stickers. ADA With a simple roll of clear tape, you can put them a lot of places.

I read an analysis of sucessful and failed non violent revolutions; one feature of the sucessful ones was to diminish the loyalty of troops and police to the government.

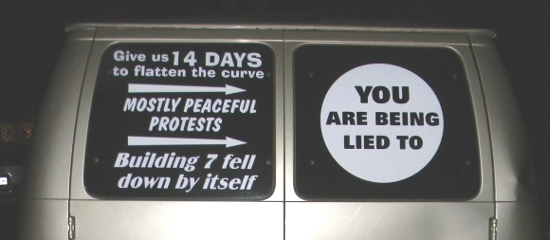

Here’s the back of a van with a message about the lying news media:

#whattodo What to do. Activism. Practical resistance. Fight the deep state. #activism

You’ve no doubt seen the twin vertical push guards on the front bumper of police cars, or a similar arrangement of a deer guard on a truck. So what if instead of boring old steel parts painted black, you had giant wild boar tusks there instead. I think it’s one of the coolest ideas I’ve had.

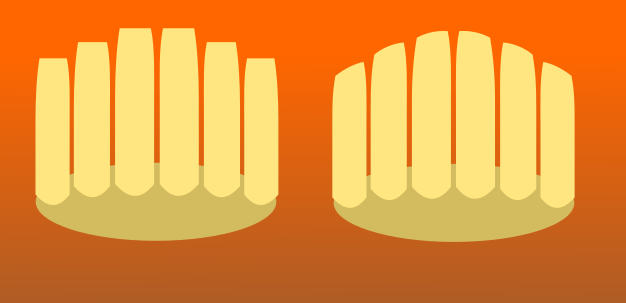

I’ve been working on it awhile, a few hours each weekend. Below are some pictures of the progress. I decided that I should also make the 6 incisor teeth between the tusks. Initially that seemed like a difficult task, but it has been a lot easier than I thought.

The tusks each consist of two pieces of 1/4 inch plate steel. Both pieces are long tall triangles. The ‘back’ one is heated in a forge and shaped to fit the curve of the tusk, then welded to the flat center piece. If this sounds confusing, the picture below should show what I mean. the silver part is an old car axle from probably the 1940s I found burried in the garden. It will be the wide part of the bumper. Looks like car bones, eh? Perfect for this project.

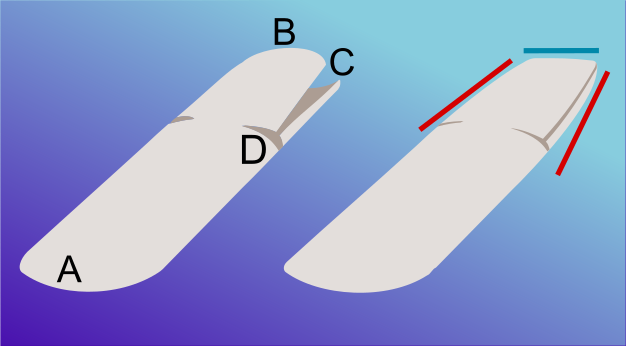

The teeth are made from 6 pieces of steel pipe. The two center teeth are 3 inch diameter pipe, 9 inches long. The next teeth going outward are 2.5 inch diameter, 8 inches long. The outside two teeth are 2 inches diameter, 7 inches long. The teeth are round at the base, but taper to a flat edge at the top. In the diagram below, A is the bottom of the pipe cut at 45 degrees. B is the top cut at 90 degrees. C is a wedge shaped cut along the side so that the two halves can be pushed together. This cut needs to be wider than you think, so that the sides also taper, as seen by the red lines at the right. D is a dual notch cut which makes putting the two halves together a lot easier. The top edges will need to be flattened with a hammer and welded as shown by the blue line to the right. Thicker pipe will require heating in this area.

The teeth are made from 6 pieces of steel pipe. The two center teeth are 3 inch diameter pipe, 9 inches long. The next teeth going outward are 2.5 inch diameter, 8 inches long. The outside two teeth are 2 inches diameter, 7 inches long. The teeth are round at the base, but taper to a flat edge at the top. In the diagram below, A is the bottom of the pipe cut at 45 degrees. B is the top cut at 90 degrees. C is a wedge shaped cut along the side so that the two halves can be pushed together. This cut needs to be wider than you think, so that the sides also taper, as seen by the red lines at the right. D is a dual notch cut which makes putting the two halves together a lot easier. The top edges will need to be flattened with a hammer and welded as shown by the blue line to the right. Thicker pipe will require heating in this area.

So the teeth decrease in size, and since they also decrease in length, the cutting line of the incisors is tilted. I’m trying for excellence of design and execution, so there’s a final consideration: I didn’t want the teeth to be staggered, but on one line. I first thought I might have to tack weld the teeth in position on the 1/4 inch jaw plate that the tusks are mounted to, in order to mark where to cut the top edge of each tooth. I didn’t want to weld them in place until all the fiberglass and bondo shaping was done, since they are so close togetether that work would be difficult. I’ll weld them inplace afterwards, using a squirt bottle with ice water in it to protect the top part of each tooth from migrating weld heat. The orange diagram below shows the difference between staggered teeth and those on a line. I didn’t need to tack weld them in place, I just held three at a time by pushing down on the base of them, then marked the line on each one with soap stone.

The teeth have had their fist layer of fiberglass in this picture, it’s to cover the gap created by my poor torch work. It was like some of these old pieces of pipe had a layer of mud inside them. When I went to cut with the torch, sometimes the metal would just turn into a puddle of liquid, then blow out a hole that was too big. Fiberglass will fix it.

In the next picture I have taken a thin cutting wheel on a four inch angle grinder and made notches along the edges of the tusks. This is for the thin wire, which is shown in the second picture. The third picture shows where I started putting fibersglass on the wire. It will work better when I use gravity for me, not against me. This is the progress from the weekend of October 16th, 2022.

A friend gave me this old homelight chain saw. It runs, but I knew that if I started using it without painting it, it might never get painted. So here are the before and after pictures. besides painting, I also cleaned parts with steel wool.