I kind of have the days of the week designated for certain things. 5 days I work for money, or something related to that; Saturday is for rest, time with the kids, and fun stuff. Sunday afternoon is maintenance day.

This last Saturday, my wife and kids went to help with a ministry that uses horses to work with inner city kids from troubled homes. She left the littlest guy home with me, because he was just getting over a slight illness, and she knew he would get tired too fast. A few days prior, I had finally received the special screws for my newly acquired jointer. I want to paint the jointer and table saw before I put them into use; otherwise it would be a long time before they ever get painted. But I knew that cleaning, masking, and painting the two tools and the bench would be way too boring for the little guy (Nolan), so I opted for removing the front bumper of the 1951 Chevrolet truck instead. I heated the nuts to orange hot while he watched and told me if I had done the other side enough. Then he helped use tools to remove the bolts and nuts. I also cleaned, primed, and painted the frame near the bumper, so that maybe I can leave the bumper on when I do the rest of the frame.

Think about the different kinds of metal, and the ways they are used in a restoration project like this. Steel is iron with varying small amounts of carbon added. Pure iron is actually the softest of the ferrous products. It’s used in the center of electric motors so that they don’t become permanently magnetized. Low carbon steel is used in places like the frame, and the sheet metal body parts. High carbon steel is used for leaf springs, which, if taken from a junk car, can be used to make knives. The vehicle also contains Chrome, and copper.

Think about the different kinds of metal, and the ways they are used in a restoration project like this. Steel is iron with varying small amounts of carbon added. Pure iron is actually the softest of the ferrous products. It’s used in the center of electric motors so that they don’t become permanently magnetized. Low carbon steel is used in places like the frame, and the sheet metal body parts. High carbon steel is used for leaf springs, which, if taken from a junk car, can be used to make knives. The vehicle also contains Chrome, and copper.

The Bible, in the Book of Romans, says: “For the invisible things of him from the creation of the world are clearly seen, being understood by the things that are made, even his eternal power and Godhead…” As time goes by, I am increasingly worshiping God as I work with all the different metals, woods, and other materials He has made. Sometimes I refer to Him as “The envy of the artists”. We are continually walking through His art gallery.

Here’s are a few pictures of body work on the 1987 Toyota truck. In an earlier post, I talked about a tool I made, to put a flange on the edge of sheet metal; so that there would be a step down, which make room for additional sheet metal, rivets, and bondo. As it turns out, there was already a tool like that. It’s called a Flange Tool. I got one at Harbor Freight; and it works great. Look closely at the picture of the front fender, and you can see the flange there. The back fender is coming along, this area used to have lots of big rust holes.

My wife was able to get some nice, real hardwood flooring to use in the bathroom. So that will be a house restoration project. The first thing to do for that project was to make a composting toilet, which will be used in a sectioned off area of the old corn crib, in the barn. This house is probably 100 years old, so there’s no telling what odd workmanship we’ll encounter as we take on the flooring project, so I want an alternate toilet. The container is a blue drum cut in half.

My wife was able to get some nice, real hardwood flooring to use in the bathroom. So that will be a house restoration project. The first thing to do for that project was to make a composting toilet, which will be used in a sectioned off area of the old corn crib, in the barn. This house is probably 100 years old, so there’s no telling what odd workmanship we’ll encounter as we take on the flooring project, so I want an alternate toilet. The container is a blue drum cut in half.

In a previous post, I showed how we restored a metal cart. Here’s a picture of the children playing with it. They devised a front axle, so it’s easier to pull and push around. They use it for work too.

In a previous post, I showed how we restored a metal cart. Here’s a picture of the children playing with it. They devised a front axle, so it’s easier to pull and push around. They use it for work too.

Finally, as the daylight was ending, we got one of our world’s best cloud shows, just before it rained. The sun was setting in the west, but this cloud was in the south. The next picture is facing southeast. The next picture is facing west. Finally, it all ended. More pictures of this can be seen at my regular blog, as soon as I make a post there.

Finally, as the daylight was ending, we got one of our world’s best cloud shows, just before it rained. The sun was setting in the west, but this cloud was in the south. The next picture is facing southeast. The next picture is facing west. Finally, it all ended. More pictures of this can be seen at my regular blog, as soon as I make a post there.

What you’re seeing are two benches. The closer one is wood, and has a motor and grinder mounted on it. The second one is steel, it has a jointer on the closer end; and a table saw on the end closest to the gold van. The lower shelf has a large electric motor.

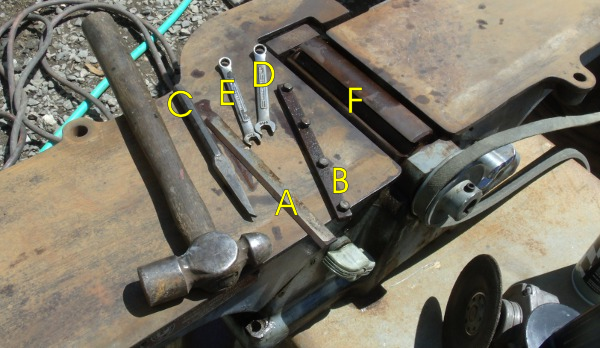

What you’re seeing are two benches. The closer one is wood, and has a motor and grinder mounted on it. The second one is steel, it has a jointer on the closer end; and a table saw on the end closest to the gold van. The lower shelf has a large electric motor. Here’s what was difficult: All these tools and parts are setting on half of the jointer top, This half raises and lowers at an angle, The places where it contacted the jointer body were rusted together. After setting a week with penetrating oil, the parts became free, and will now move as needed. I’ve never had good results using the oil this way, until today.

Here’s what was difficult: All these tools and parts are setting on half of the jointer top, This half raises and lowers at an angle, The places where it contacted the jointer body were rusted together. After setting a week with penetrating oil, the parts became free, and will now move as needed. I’ve never had good results using the oil this way, until today.

Some info about the rest of the pictures: The blue car is a Super Bird in progress, there’s a Challenger, and a beautiful Dodge truck. The engine block is a 440 cubic inch block, typical of police car motors back then. There’s a distibutor rebuilding machine, and a hemi in a crate. The complete 440 engine is in the Super Bird.

Some info about the rest of the pictures: The blue car is a Super Bird in progress, there’s a Challenger, and a beautiful Dodge truck. The engine block is a 440 cubic inch block, typical of police car motors back then. There’s a distibutor rebuilding machine, and a hemi in a crate. The complete 440 engine is in the Super Bird.

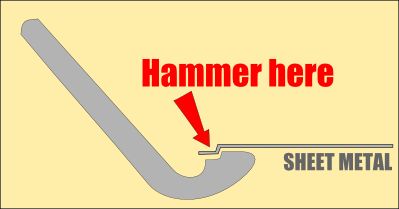

The body work involved an experiment I’ve been thinking about for a few months. I wanted a steel tool that was sort of hook shaped, with a step like drop on the upper surface. The idea being to put the hooked part just inside the edge of a hole on the body. This is after the area has been cleaned and painted inside and out. Regardless of what people say, properly treated rust won’t continue to spread, if you keep the oxygen away from it. Air and water are oxygen sources. Anyway, I also made a small straight peen hammer. The hammer is used to hit the sheet metal and make it conform to the step part of the hook tool.

The body work involved an experiment I’ve been thinking about for a few months. I wanted a steel tool that was sort of hook shaped, with a step like drop on the upper surface. The idea being to put the hooked part just inside the edge of a hole on the body. This is after the area has been cleaned and painted inside and out. Regardless of what people say, properly treated rust won’t continue to spread, if you keep the oxygen away from it. Air and water are oxygen sources. Anyway, I also made a small straight peen hammer. The hammer is used to hit the sheet metal and make it conform to the step part of the hook tool.