Since I’ve been preparing to make my latest mural, I’ve been studying tress more. I made a page to share these observations as I make them, you can see it here.

The Restoration Posts

The Art of Trees.

Betsy Ross Flag Painted on the Warehouse

I made a page about painting the Betsy Ross flag with my son, you can see it here.

Here’s a picture from down the hillside:

.

Painted White At Last

Finally, after getting this building moved here, and the prep work done, I was able to paint it with two coats of white. I used an airless sprayer, and if you’ve ever used one to paint a large object, you’ll never want to use a slower tool. There are 14 boards on the side not showing, it’s the side that can be seen best from the street. I plan to use those boards as a layout form a Betsy Ross flag. More later.

Wood of the Warehouse.

The lumber that was sold and used in times past was of a higher grade than much of what’s sold now. Here’s a link to a post about the wood of the warehouse:

The Wood Building Has Landed!

I think it was 2 or 3 years ago, a neighbor gave me this wood building, but I haven’t been able to move it until now. He described it as a “National Guard WW2 era portable wood building”. It was a huge task getting it off the trailer without a crane, and on slanted ground. We’ve lived here at least 6 years, and the back yard didn’t seem very slanted, but it drops 14 inches in 12 feet. That makes the job a lot more work. I’ll edit this page later with the details, but I need to get it posted now, so here it is. This will be the warehouse for my Quill and Blade retail store.

New Directions, Old Directions

I’ve spent a lot of time on social media trying to engage people about political matters. There came a point when I realized it was futile, so I’ve stopped that. I’m now making a few videos, and talking to people in person. There are more details at youtube, here’s one: https://www.youtube.com/watch?v=0027GZgga8E&t=28s

Other videos talk about plans to get a table at a gun show; which I did. Here’s a picture of the first show, I plan to do more, and I’ll make a video describing what happened while I was there. It was a big success. I would like to have handed out more printed material, but I was talking constantly to people who stopped at my table. Saturday, I was contacted by a man with a radio talk show who said he would be in contact, and Sunday I was asked to be a speaker at a constitutional rights group.

As for old directions, what initially inspired all this was a return to making signs and putting them out.

Two Restoration Projects

The first is my own, a 1951 Chevrolet 2 ton truck. The motor runs, but it needs all new brake lines, conversion to 12 volt, the frame sandblasted and painted, the body painted, and some window glass. One of the big delays in painting it has been the hood. It’s one of those can’t do this part until I first do that; can’t do that part until I do this other thing, and so on. Specifically, there are dings in the hood, I don’t want to fill those until the rusted braces have been fixed, don’t want to put the braces in place until I sand and repaint the inside of the hood.

Making replacement braces was the slow part, but they’re done, and the inside of the hood is painted an off black color. Now I can really move on finishing the body work and painting the truck. Forest Green, I think. The other project is for a customer, it’s a cast iron and wood bench made for the Coca Cola company. I sandblasted the old paint off, then, in the picture below, I used a wire wheel on a 4 inch angle grider to polish away the sandblast texture. It still had a very rough sand cast texture, so I sprayed it with a heavy coat of automotive sandable primer. It’s an off the shelf product from O’Reiley’s Auto Parts. I’ve never used it before, but it’s the best spraying primer I’ve ever used. I REALLY liked the way it handled in the spray gun. What’s left is to see how ell it sands. It will be a problem if it’s too rubbery.

The other project is for a customer, it’s a cast iron and wood bench made for the Coca Cola company. I sandblasted the old paint off, then, in the picture below, I used a wire wheel on a 4 inch angle grider to polish away the sandblast texture. It still had a very rough sand cast texture, so I sprayed it with a heavy coat of automotive sandable primer. It’s an off the shelf product from O’Reiley’s Auto Parts. I’ve never used it before, but it’s the best spraying primer I’ve ever used. I REALLY liked the way it handled in the spray gun. What’s left is to see how ell it sands. It will be a problem if it’s too rubbery.

We Worked, We Talked . . .

Today I got to spend some time with my two youngest sons. I looked at a “stuff to do with the kids” list I made a while back. It had a number of art or mural projects, but I wanted to do something different. Art is fine if you like it, and can sell it, but it’s not for everybody; and it’s not as practical as other skills.

I looked at the vacuum boost master cylinder from the 1951 Chevrolet truck that is in my last post about sandblasting, and realized we could work on it together. It’s difficult to remember, but a lot of projects you work on are good for working on together with the kids. I’ll repost the before and after pictures of it being sandblasted.

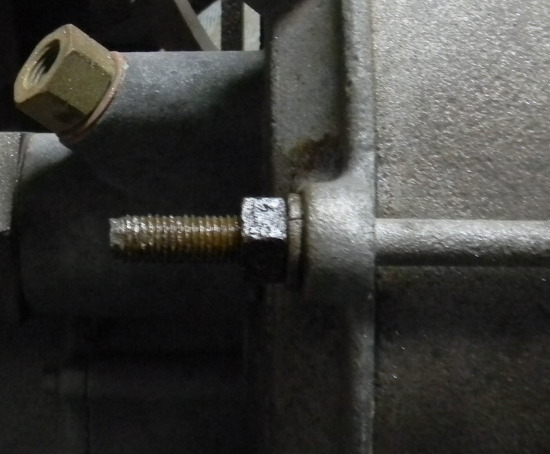

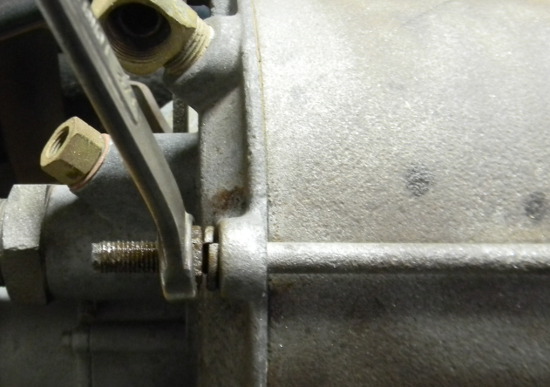

Today, I wanted to take it apart, and see how much repair work it needed. I was told it likely had sitting water in the big air cylinder part, and rust pits in the metal. The first step was to deal with the four long bolts holding it together. They had been cleaned up pretty well where the blast operation hit them, but not on the other side. So I borrowed a tap and die set, and found the 5/16 fine thread die, often called a “thread chaser” I explained how it worked to the boys, and carefully worked it onto the old threads. then we turned it back and forth, while oiling the threads.

Today, I wanted to take it apart, and see how much repair work it needed. I was told it likely had sitting water in the big air cylinder part, and rust pits in the metal. The first step was to deal with the four long bolts holding it together. They had been cleaned up pretty well where the blast operation hit them, but not on the other side. So I borrowed a tap and die set, and found the 5/16 fine thread die, often called a “thread chaser” I explained how it worked to the boys, and carefully worked it onto the old threads. then we turned it back and forth, while oiling the threads.

The conversation went a lot of places, and even ended up at Lincoln in the Civil War era. That might have happened after I discovered something interesting: lock washers that still had their spring in them. The truck is 68 years old, and it’s possible that this unit has been rebuilt or replaced in that time. But It’s probably at least 30 or 40 years old. These lock washers have been held flat for all those years, but when I loosened the nuts holding them down, they sprang open.

That to me is an amazing property of spring steel. Other old springs last a long time too. Old springs in guns last a long time. Even guns a hundred years old have good springs. Other types of steel will conform to the held shape after years in position. So here’s two pictures of the lock washers as they’re being loosened.

I finally got the housing off, and found this weird brown crumbly stuff inside. Sort of like sawdust with oil on it. the stuff would hold together is squeezed, and felt wet. But it burned, as seen in the picture with the mouse drawn arrow.

I finally got the housing off, and found this weird brown crumbly stuff inside. Sort of like sawdust with oil on it. the stuff would hold together is squeezed, and felt wet. But it burned, as seen in the picture with the mouse drawn arrow.

The good news was how clean and rust free the inside of the housing was. No need for a new part here.

The good news was how clean and rust free the inside of the housing was. No need for a new part here. In the last picture, you can see more parts. Under the big spring are two plates that make up the piston. The lower one has fresh looking oil near the center, but the picture makes it look odd. The compression ring is some sort of felt or leather, soaked in oil. Anyway, it was a great rainy day project with the two boys.

In the last picture, you can see more parts. Under the big spring are two plates that make up the piston. The lower one has fresh looking oil near the center, but the picture makes it look odd. The compression ring is some sort of felt or leather, soaked in oil. Anyway, it was a great rainy day project with the two boys.

Testing a Sandblast Cabinet

My son was given a sandblast cabinet that a shop no longer needed. It’s very nice, in two parts. One is the cabinet where the work is done, the other part is an air filter, which filters the air in the cabinet, so that there’s not a bunch of dust blown in the shop. It probably also helps with visibility in the cabinet.

It wasn’t being used, because it needed a couple parts. I needed it for a small job, so I got those parts. The job is a wood and cast iron bench that advertises Coca-Cola.  I’ll hand letter it back to the original colors. There are three iron pieces; two sides, and a plaque that goes in the middle of the bench back. I’ll make a page about the whole process after it’s done.

I’ll hand letter it back to the original colors. There are three iron pieces; two sides, and a plaque that goes in the middle of the bench back. I’ll make a page about the whole process after it’s done. I have a 1951 Chevrolet truck; below is a picture of the vacuum boost unit for the brake system. I could have removed more rust, but the sandblast cabinet was having some problems, so I cut it short. I think it will clean up just fine.

I have a 1951 Chevrolet truck; below is a picture of the vacuum boost unit for the brake system. I could have removed more rust, but the sandblast cabinet was having some problems, so I cut it short. I think it will clean up just fine.

New Directions

I became an old school sign painter in the 1980’s. The sign trade has undergone major changes, and I’ve had to adapt as best I can, while trying to live withing certain parameters. One of those is to try and live without debt. I resisted computer made signs for a long time, but finally waded into those waters. I have preowned vinyl cutting plotters, but even those are outdated, For the most part, the trade has gone to wide format printing.

Think about how much faster it is to print an 18 inch by 24 inch real estate sign. All the lettering, colors, and logos are on one piece of vinyl; or printed directly onto the substrate. Man, that’s fast. So I figured that the printed method would be the last development for quite awhile, in terms of technology. I thought that it might be worthwhile going in debt to buy one, but that would be a $25000 or $50000 ticket. While I was very slowly contemplating it,. and interesting thing happened. People started selling printed signs online at very cheap prices. I’m SO GLAD I didn’t buy a machine.

As it is, I do a few painted signs, but most of my work is painting equipment. Above is a recent painting job on an MG hood. The changes have left me in the position of being older, with no retirement. For years, I’ve had ideas of things I could make and sell, but was never sure how to get them to market. I’m also very interested in historic things. Once I changed my thinking to being a guy who sold things, regardless of who made them, my path became much clearer, and I really enjoy it.

So that’s what I’m doing, starting a new business. It’s called Quill & Blade Country Store and trading post. Much of my time lately has been to work on that project. You can see more at this site: Quill & Blade

I’ve been restoring some neat tools lately, I even fired up my coal fired forge over the weekend. I’ll post pictures as soon as I can. I also want to make videos about current religious and political events. Here’s a wintertime scene from an abrupt change in the weather.